Most Important Features And Benefits Of The Cosmetic Cream Mixing Tank

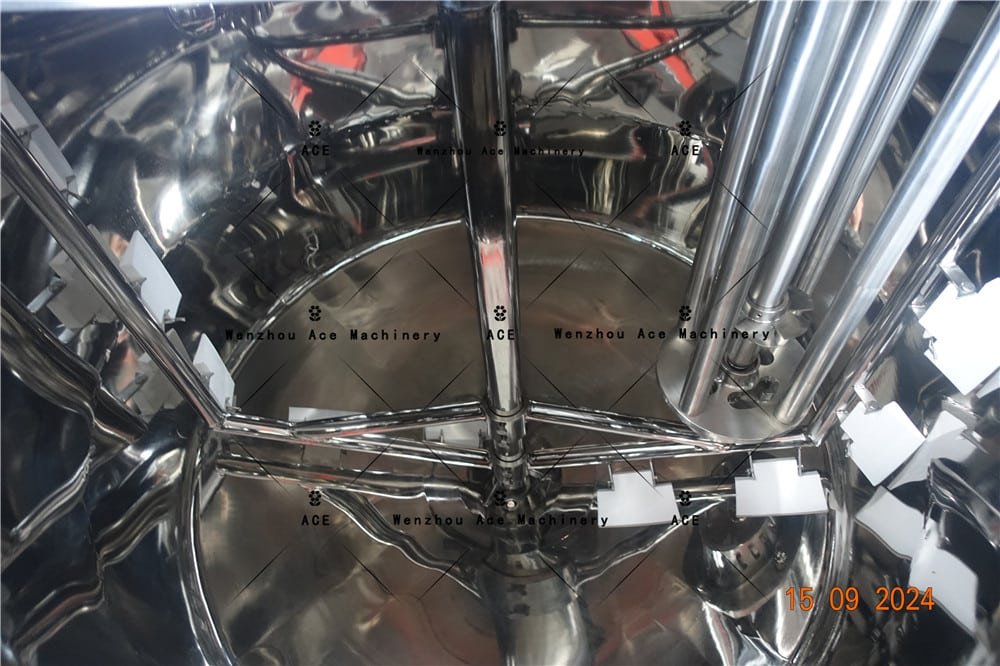

High Shear Mixer

Our Cosmetic Cream Mixing Tank comes with high-end equipment that incorporates a high shear mixer. Uniform blending of ingredients is guaranteed as the mixing process of the tank is done via high shear. The high shear blender is great for emulsifying materials into creamy pastes or liquids, which is necessary for the production of top quality cream and lotion for ease of use and uniform texture and viscosity.

Scraper Mixer

The scraper mixer enhances the quality of the mixing process while preventing the loss of any material that may have been stuck to the sides of the mixing tank, and as a consequence increases product yield. This feature ensures that your batch is fully blended, ensuring no cream production waste is left behind and consistency for all base emulsions is reached.

Electric Heating

The electric heating unit enables accurate heating control. This ensures that the ingredients are mixed at the appropriate temperature. Such a feature is important for emulsions and other sensitive ingredients, since the temperature has to be controlled to ensure stability and quality of the product.

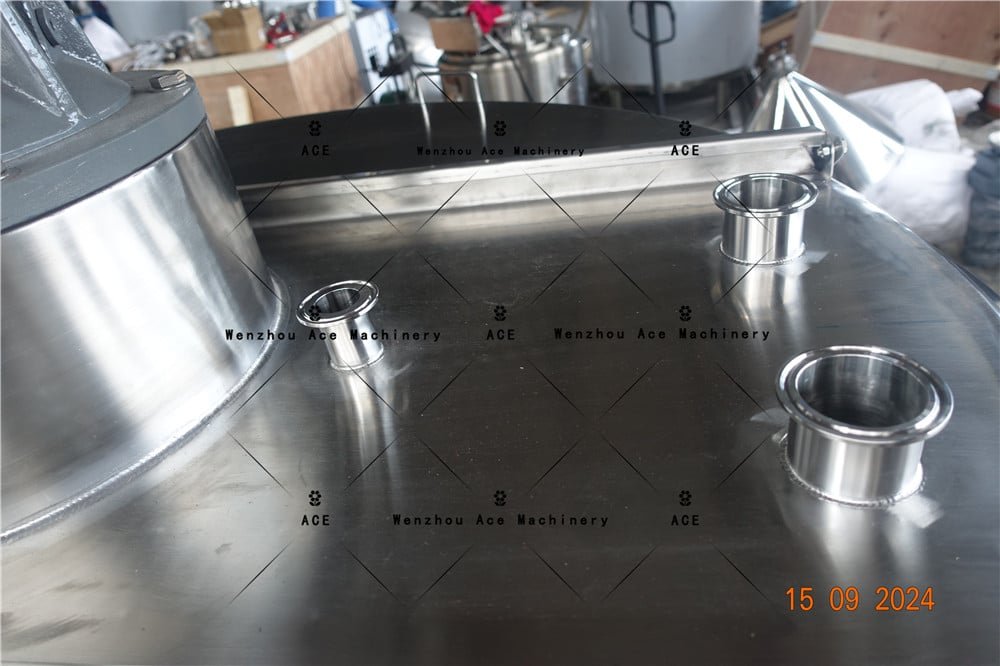

Lobe Pump

The tank is equipped with a lobe pump and therefore the mixed cream or cosmetic can be easily transferred from the mixing tank to the subsequent stage of production without the risk of contamination and smooth tissue processing.

Customizable Sizes

A Cosmetic Cream Mixing Tank designed as a stand-alone unit is available in volumes from 50 liters to 30,000 liters. We can tailor a tank to meet the requirements of small laboratories or large scale manufacturing plants.

Material Options

Select between 316L stainless steel for better compatibility with corrosive materials, or the more versatile 304 stainless steel. Both materials are long-lasting, easily cleaned, and offer the requisite hygiene levels, which are essential in the production of cosmetics.

Versatility

Our mixing tank is suitable for different types of cosmetic products including creams, lotions, gels, and serums. This makes it ideal for use in the production of anti-aging creams, moisturizing lotions, and skin serums.

Voltage and Power

In order to meet various operational needs, we provide power and voltage ranges starting from 110V up to 600V. We also provide power options from 1.5KW to 55KW. This flexibility enhances the functionality of your tank as it can be operated in different settings and fulfill your facility’s energy needs.

How to Incorporate Cosmetic Cream Emulsifier Tank into Your Production Cycle

In the case of cosmetic cream production, the Cosmetic Cream Mixing Tank is easy to use:

- Step 1: Pour your primary components, oils, emulsifiers, water, active components, etc., into the tank.

- Step 2: Switch on the electric heater and bring your formula up to the desired temperature. The high shear mixer will start blending the components into a smooth emulsion.

- Step 3: The scraper mixer will keep stirring the mixture so that any residual product on the tank walls will be scraped off.

- Step 4: After the cream or lotion is entirely emulsified, the rotor pump will convey the product to the next production step or to the storage tanks.

With these straightforward steps, you are able to produce differentiated, top-grade cosmetic products efficiently.

Customization and Size Options

Every cosmetic manufacturer has different requirements, and that’s why we have specific sizes available for the Cosmetic Cream Mixing Tank. Starting with small batches or scaling up to larger production runs, no matter your requirements, we can accommodate your needs. From 50 liters to 30,000 liters, the tank’s size is versatile enough for all operational scales.

Commonly Asked Questions

- 1. Can I customize the tank size?

- Yes. We can tailor the tank according to your production requirements, starting from liters to finishing at 30,000 liters.

- 2. What materials are available for the mixing tank?

- Our Cosmetic Cream Mixing Tank is available in 316L or 304 stainless steel. 316L is great for cosmetic manufacturers needing superior corrosion resistance, while 304 is a standard option for basic applications.

- 3. What voltage options are available?

- The voltage options range from 110V to 600V to accommodate the power requirements of your facility.

- 4. What power options are available?

- Starting with 1.5KW and going up to 55KW, we will provide you power options according to the size of the tank and your production capabilities.

- 5. Is it possible to use the tank for various cosmetic products?

- Certainly, the Cosmetic Cream Mixing Tank is multipurpose as it can be employed with multiple types of cosmetics products such as lotions, creams, gels, and serums.

- 6. Is the tank cleaning straightforward?

- Cleaning the tank is easy because it is made out of 316L and 304 stainless steel, which is free from bacteria and easy to maintain, which is needed for cosmetics manufacturing.

Conclusion

The Cosmetics industry will find the Cosmetic Cream Mixing Tank an invaluable addition to their production lines. With high shear mixing, electric heating, rotor pump, and scraper mixer combined, the tank is unparalleled in producing high-quality creams and lotions in an efficient and cost-effective manner. When considering a production load, whether small or large, our variety of options and sizes can be tailored specific to your expectations. For more information on how the Cosmetic Cream Mixing Tank can improve your production rate and overall quality of the product, reach out to us now.

Order then and see improved precision in your mixing along with enhanced quality in your cosmetic products.