Why Use a Mixing Tank with Scraper for Viscous Products?

If you are into production and dealing with viscous products such as creams or pastes, the production processes may sometimes be complicated. For instance, a huge chunk of finished product remains on the tank surface when a batch of viscous production is completed. This is certainly a waste and sometimes requires the use of a special blending tool called a mixing tank with scraper. Scraper scraping allows the tank surface to be cleared from the previously mixed product, thus minimizing when scrappers are utilized.

Benefits of Using a Mixing Tank with Scraper

- Increased Efficiency of Mixing: Provides a more consistent and uniform product, as all contents come into contact with the mixing blades and cold spots no longer exist.

- Minimized Waste of Product: Thanks to the scrapper, there will be minimal raw material projections at the periphery of the tank after pumping, thus saving material costs.

Enhanced Features of Heating/Cooling Systems of a 500-Liter Mixing Tank with Scraper

As a general rule, the mixing tank gets the job done by constantly scraping material off the walls, facilitating effective heat avalanche.

Cost Saving:

In terms of cost-saving due to less manual intervention, achieving prompt blending and mixing cycles can now be a reality.

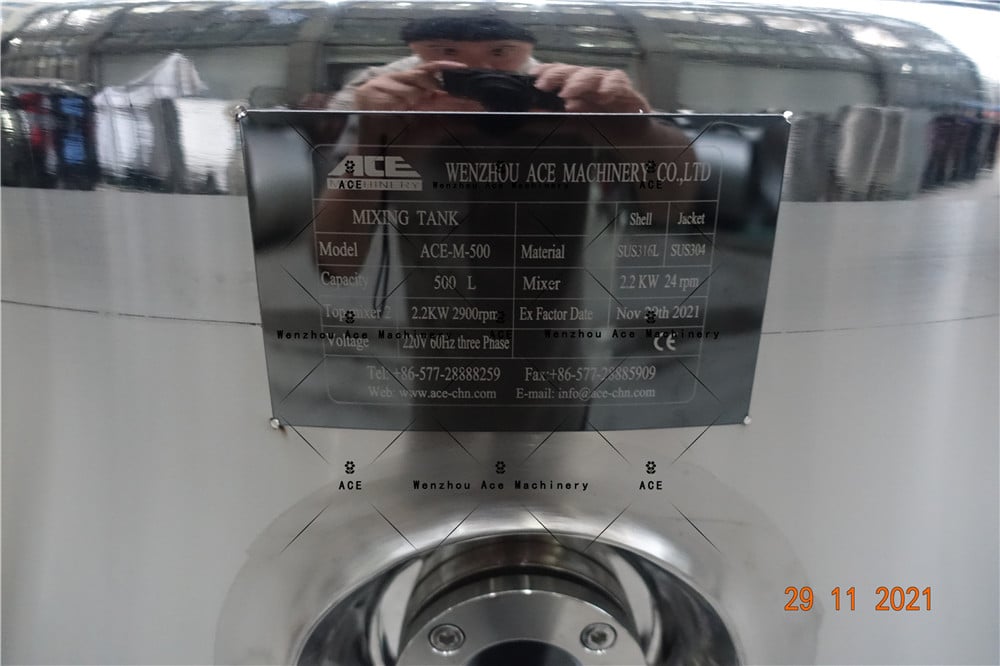

Main Parts of a 500-Liter Mixing Tank

It would be ideal in getting the most benefit out of a mixing tank with scraper to understand the components it is made up of for your required application.

Stainless Steel Tank

The 500 liter tank built from good quality stainless steel is not only corrosion resistant but is also tough and can withstand food grade as well industrial use.

Components of a Scraper Agitator

While the blades are attached to the scraping arms that are attached to the agitators, as the agitator rotates, the arms assist in scraping the interior walls which ultimately leads to less material collection on them while aiding even mixing of the entire material.

Motor & Gearbox

Power of the robust motor enables the mixing of thicker materials, while the gearbox provides the motor with a controlled speed & torque that will meet the requirements depending on the different types of blending.

Temperature Control Jacket

The jacket is intended to help constate the internal temperature of the tank. Therefore, for those tanks where the internal temperature needs to increase or decrease, the jacket would be simple to use, which would promote easy use for applicable species.

Uses of 500-Liter Mixing Tank with Scraper

A mixing tank with a scraper is highly adaptable to the needs of specific industries. It offers several uses, such as these:

Food and Beverage Industry

This is where the tangy ketchup, creamy mayonnaise or even confectionery items are mixed using this tank. It scrapes pastes and creams, thus keeping the texture intact and even.

Cosmetics

The lotion, cream and gel tend to have specific use. This tank is ideal for mixing such products as it does not allow air bubbles to form in between.

Chemical Industry

Mixing of substances like polymers and varnishes in a blender which requires evenness is ideal in this tank since it mixes them perfectly.

Pharmaceuticals

With the use of this blender, the gels and creams can be homogeneously emulsified and mixed, allowing a better distribution of active constituents.

Considerations When Choosing a 500-Liter Mixing Tank with Scraper

Several vital considerations including the following should be observed to ensure choosing the best 500-Liter Mixing Tank with Liquid Sump is right for a given business.

Material Compatibility

Stainless steel is common for being very durable and good for hygiene but make sure the finishing of the tank’s interior is appropriate towards key parameters of the product being mixed.

Scraper Type and Configuration

There are many types of scrapers depending on how viscous the material is. High viscous materials do better with scrapers which are bigger or more flexible, or those that are designed to do so in order to eliminate build up even more.

Heating or Cooling Capability

Products that require a specific temperature to manage their processing can use a mixing tank with heating or cooling jackets. Ensure that the tank can operate in the required range for your product.

Control Panel and Programmability

When it comes to technologically advanced tanks, there is a control panel that enables the operator to fix the mixing speed, scraper speed, and temperature settings that provide greater flexibility and accuracy in Australia.

Maintenance and Longevity of the Mixing Tank with Scraper

To optimally operate your 500 liter mixing tank with scraper, it is necessary to perform regular maintenance. Having an appropriate scrapper, stirring device, and tank cleaning process can help avoid excessive deposits and promote operational efficiency of the entire equipment. Many tanks come with Clean-in-Place (CIP) systems which allow users to wash down the tank after every production cycle, which is important in the food and drug industries.

Frequently Asked Questions

What types of products are best suited for a mixing tank with scraper?

A mixing tank with scraper is ideal for thick substances like pastes, creams, gels and such. The scraper minimizes wastage, provides adequate mixing of products, and homogenizes the resulting product.

Why is the scraper function important in a mixing tank?

The use of the scraper in mixing tanks also provides a more efficient consistence of the end product by eliminating the chances of certain materials sticking at the walls of the structure.

Is the 500 liter tank size ideal for small or large production runs?

Apart from this being a large size tank, it is purposely designed for manufacturers who conduct medium range production runs, as it is very versatile and efficient for both large and small manufacturers.

Can the 500-liter mixing tank with scraper take on temperature-sensitive products?

Yes, there are quite a number of these tanks that are equipped with heating or cooling jackets which would suit the specific temperature requirement which is appropriate for food items and cosmetics.

How often should the scraper blades be replaced?

It is recommended that scraper blades used in the tank be replaced as necessary after evaluating the degree to which they have worn out, it is good to note that this will vary according to the frequency of use of the tanks, the viscosity of the mixtures and preventive maintenance performed.

Is it possible to use this tank to automate the mixing process?

Of course, there are numerous 500 liter mixing tanks that come with scrapers which work off of programmed controls, thus the mixing parameters can be preset and would require minimal monitoring.

Final Thoughts: Get A 500-Litre Mixing Tank With Scraper If You Want Better Results

A 500 liter mixing tank with a scraper is a valuable asset for any business which requires smooth and evenly mixed high viscosity types of materials. Its scraper technology guarantees minimal wastage, uniformity, and quality in temperature for heat sensitive substances. From food processing to cosmetic production, from pharmaceuticals to chemicals, a mixing tank with a scraper can simplify your operations, enhance your products, and efficiently use your resources.

Want to boost your production process? Get in touch with us right now and let’s talk about the 500 liter mixing tank with a scraper and find the best model for your blending operation.