Key Features of Premium Chemical Mixing Tanks

316L Stainless Steel: A Durable Material for Chemical Mixing

Another main feature of our chemical mixing tanks is premium 316L stainless steel construction, one of the important features to cover all main features of pharmaceutical equipment, whereas cost dominated over apparent specific capacity.

Hygienic Surface

The 316L stainless steel does not have any rough patches, thus limiting contamination. It can be cleaned and sanitized with minimal effort so that, chemical mixing processes observed in practice are able to meet high industry standards.

Durability

316L stainless steel contains strong construction, enabling its use in the long run with the ability to resist wear and tear even in the extreme high pressure or high temperature environments. This provides great benefits in terms of increasing the production efficiency margins for firms’ operating procedures.

Customizable Heating Options: Steam or Electric

Steam Heating

For processes that require temperature control, steam heating is preferred since heat is supplied uniformly around every part of the tank. This therefore is very beneficial to industries like pharmaceutical industries where product quality depends a lot on temperature. Also, steam heating does and use a lot of energy and hence is economically feasible on a big scale.

Electric Heating

For those seeking comfort in the usage of a heating system that offers a much simpler and more versatile option than the others, Electric heating is also in the list of available heating systems. This technique is simple in installation and use which all but eliminates the dependencies on an external steam source to achieve heat generation. Electric heating is usually the option of choice for smaller processes or when installation of a steam system is impractical.

Capacity: 50 to 30,000 Liters

Every industry has its specific requirements, especially regarding mixing, which explains the reason why our chemical mixing tanks can be designed and manufactured with different capacities ranging from 50 liters to 30,000 liters. Whether you are looking for a small tank for any experimental processes or a complete production vessel for the mass production of materials, we have a solution for you.

Volume Options

- 50 to 500 Liters: Center around R&D as well as small batch/pilot production. These tanks achieve exceptional precision while providing operational flexibility to companies in an expansion phase or experimenting with fresh formulations.

- 500 to 5,000 Liters: Intended for medium volume operations, these tanks are very well positioned in terms of capacity relative to operational performance. They are typically utilized for the cosmetics, food, and pharmaceutical industries that require the processing of moderate volume materials.

- 5,000 to 30,000 Liters: For mass industrial production, these tanks feature the capacity necessary for high-volume processes. These tanks are commonly found in the chemical plants as the nature of the processes such as continuous or batch production demands effective mixing.

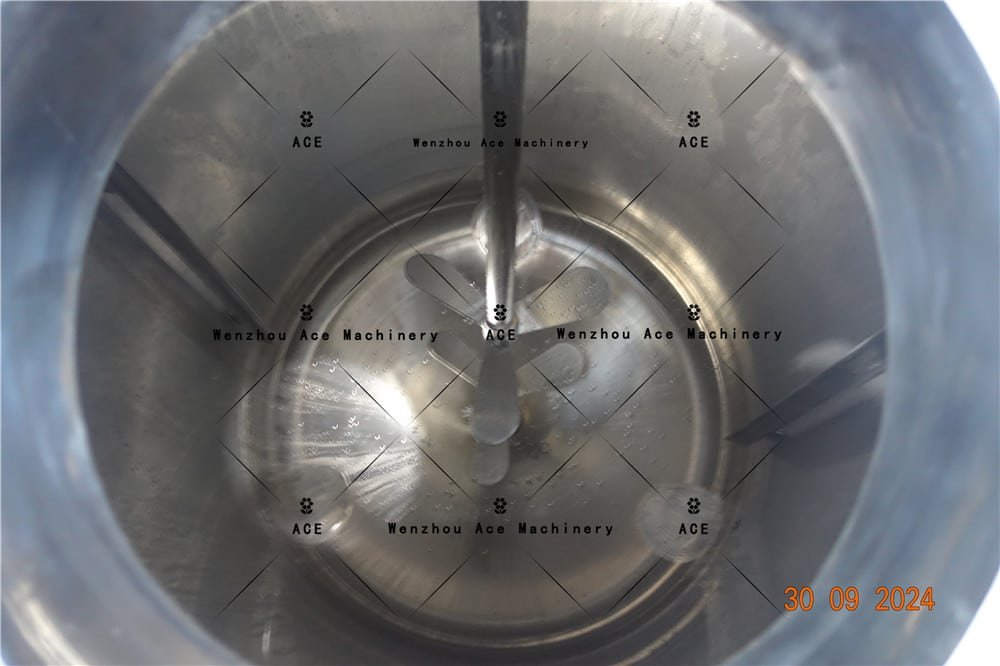

Agitating Devices and Performance Optimization

Each tank can be furnished with agitating devices, mixing blades and other works to improve performance. Moreover, other controls may be incorporated to control speed, temperature, and time for optimal performance.

Why Choose Our Chemical Mixing Tank?

Multipurpose Structure

Retaining an option for the alteration of the size and the heating methods of the chemical mixing tanks, those can be adapted to meet your production standards. From pharmaceutical, cosmetics and food processing, coating, and chemical industries, our tanks do not disappoint the job significantly.

Economical Heating

Steam or electric heating may be selected, with features incurring minimum operational costs for efficient, energy efficient tanks being available over time. For steam heating, temperature control will be the best that can be obtained and for electric heating, more flexible applications can be offered.

Guaranteed and Rugged

Due to the fact that these tanks are made of 316L stainless steel, they are designed to operate in the most demanding surroundings and therefore last longer without the need to be changed repairing them.

Customizable Features

Custom tank mixing solutions encompass a wide range of options including tank volume, heating units and tank mixers which can all alternated according to your specifications.

Invest in Quality and Performance

Where reliability, toughness, as well as efficiency are concerned, that’s exactly what the chemical mixing tanks we offer do. The mixing tanks made of 316L stainless steel and with perfect dimensions starting from 50 LTS to 30,000 LTS, heating of either steam or electric type are targeted for each of your industry needs.

Quality mixing processes is something that should not be compromised at any moment. Get in touch with us today so that you can find out how you can use our chemical mixing tanks to enhance both your production processes and the quality of the final products every single time. Our expert team will be pleased to assist you in choosing the right mixing tank for your process. There is no need to wait any longer! Request a quote online to finalize your order, and you will be on your way to better chemical mixing capabilities!