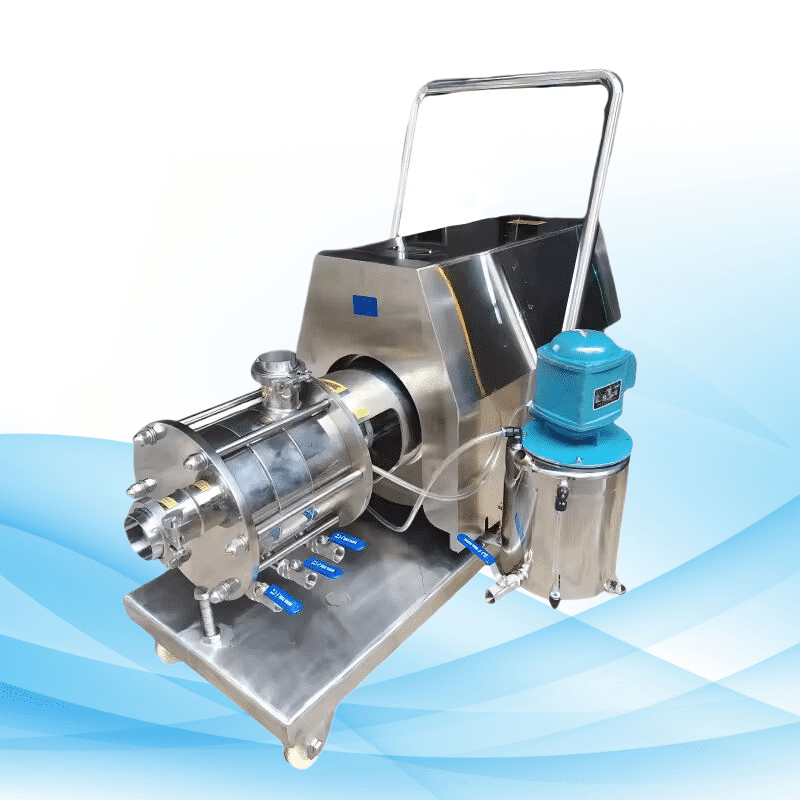

- Material:SUS304/ SUS 316L

- Power: 1.5-45 kw

- Voltage: 110V 220V 380V 440V 480V

- Capacity: 0-75 T/h

- Speed: 3400 rpm/min

- Customized: can add hopper

- What kind of material do you want to process?

- What’s the capacity?

- What is it used for?

- Mixing, dispersing, shearing or homogenizing?

Advantages:

- Suitable for on-line continuous production of industrialization;

- Narrow size distribution range, high evenness;

- Energy saving, time saving, high efficiency;Low noise, smooth operation;

- Eliminate the wholesale products differences;

- Material 100% by shear;

- With short distance, low-head transmission function;

- Simple to use, easy maintenance;

- Can achieve automatic control;

|

Technical Parameters

|

||||

|

Model

|

capacity (T/H)

|

Speed(RPM)

|

our Pressure (bar)

|

power(KW)

|

|

ACE-80

|

0-1.5

|

2900/3400

|

≤2Bar

|

1.5

|

|

ACE-100

|

0-3

|

2900/3400

|

2.2

|

|

|

ACE-130

|

0-4

|

2900/3400

|

4.0

|

|

|

ACE-140

|

0-5

|

2900/3400

|

5.5

|

|

|

ACE-165

|

0-8

|

2900/3400

|

7.5

|

|

|

ACE-180

|

0-12

|

2900/3400

|

11

|

|

|

ACE-185

|

0-18

|

2900/3400

|

15

|

|

|

ACE-200

|

0-25

|

2900/3400

|

22

|

|

|

ACE-210

|

0-35

|

2900/3400

|

30

|

|

|

ACE-230

|

0-50

|

1450/1700

|

45

|

|

|

ACE-245

|

0-75

|

1450/1700

|

55

|

|

|

*The above information is for reference only and can be customized according to customer requirements. *This equipment can be customized according to customer’s materials to meet the needs of the process, such as requiring greater viscosity, enhanced homogenization function, heat sensitive materials and other requirements.

|

||||

Our Mixers are Designed to Mix and Disperse Efficiently

Our advanced mixing technologies enable chemical manufacturers to improve the quality of their mixed material.

Your pre-mixes will be agglomerate-free, minimizing your mill’s maintenance costs and reducing media mill screen clogging.

- Reduce batch times

- Reduce maintenance costs

- Reduce clogged media mill screens

- Eliminate air entrainment

- Quickly eliminate agglomerates

- Increase mixing efficiency and energy efficiency while reducing total cost of ownership

- Boost yield thanks to quick and efficient blending of wet and dry ingredients into a homogeneous mixture

- Increase process and product flexibility, easily handling various formulations with different viscosity, densities, and volumes

- Cut process time, emissions and installation, energy, raw material, and maintenance costs

- Improve process flexibility by leveraging the mixing and cleaning capabilities in a single unit

- Fast return on investment and low total cost of ownership due to less waste and a more sustainable use of resources

Application

1. Fine chemical: pigment, glue, sealing compound, resin emulsifying, germicidal agent, coagulating agent 2. Petroleum chemical: lubricating grease, diesel emulsifying, asphalt modification, catalyst, paraffin emulsification

3. Bio-pharmacy : injection, antibiotic, ointment, biopreparate, capsule emulsification, sugar-coating

4.Coating&oil inks: printing ink, emulsion coating, construction coating, auto paint, coating auxiliary agent

5. Pesticides : bactericidal agent, seed coating agent, herbicide, pesticide emulsified oil, fertilizer, biological pesticide

6. Nanometer material : dispersing and dispolymerizing nanometer material, extracting nanometer products in chemical reaction

7. Food industry : juice, jam, jelly, ice cream, dairy products, additive, tea drinking.

8. Daily Chemicals : detergent, shampoo, cream, lipstick, cleaning facial milk, daily Essence

9. Paper making : pulp, adhesive, rosin emulsification, paper making additive, resin Emulsification